Introduction to the use and production of large flanges

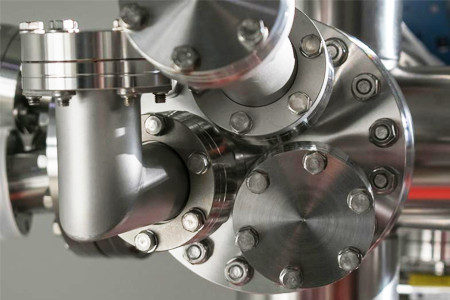

Common integral flanges include flat welding flanges and butt welding flanges. Large flanges have poor rigidity and are suitable for occasions with pressure p ≤ 4MPa; large flanges, also known as high neck flanges, have high rigidity and are suitable for occasions with high pressure and temperature.

13

2023

/

03

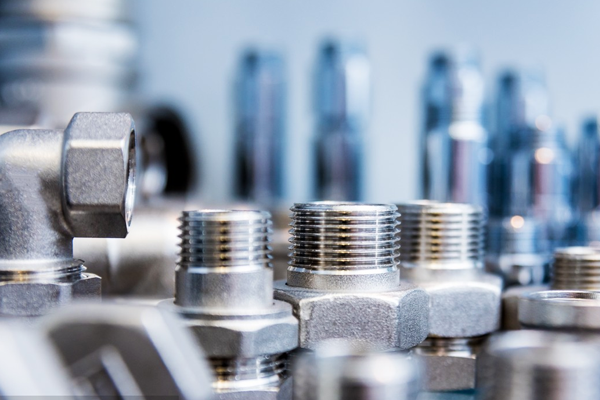

Fillet weld for socket welding

The fatigue strength of socket welded joints is lower than that of butt welded joints due to fillet welds and steep changes in geometry. However, socket welded joints are still superior to other mechanical connections.

13

2023

/

03

The flanges are gasketed. American standard flanges can be cast or threaded or welded.

This process is suitable for the production of large flanges of any specification where the ratio of the medium diameter of the stamping flange to the inner diameter of the stamping flange is greater than 1.5. Now, we produce stamping flanges and butt welding flanges. Flange flange products such as push flanges, butt welding flanges, and flat welding flanges are deeply trusted by customers. We will weld polygonal annular shells with polygonal cross-sections or polygonal sector shells with closed ends. When the pressure medium is filled with internal pressure, the section gradually changes from polygon to circle under the effect of internal pressure, and finally a circular annular shell is formed.

13

2023

/

03

Common integral flanges include flat welding flanges and butt welding flanges

In high-pressure equipment and pipelines, metal gaskets of lens type or other shapes made of copper, aluminum, No. 10 steel, and stainless steel are used. The contact width between the high-pressure gasket and the sealing surface is very narrow (line contact), and the processing finish between the sealing surface and the gasket is high.

13

2023

/

03

The fatigue strength of socket welded joints is lower than that of butt welded joints

Socket welds use fillet welds. When high structural strength requirements and high leakage risk are design considerations, socket welded joints are a better choice.

13

2023

/

03

This process is suitable for the production of large flanges of any specification where the ratio of the medium diameter of the stamping flange to the inner diameter of the stamping flange is greater than 1.5. Now, we produce stamping flanges and butt welding flanges. Flange flange products such as push flanges, butt welding flanges, and flat welding flanges are deeply trusted by customers. We will weld polygonal annular shells with polygonal cross-sections or polygonal sector shells with closed ends. When the pressure medium is filled with internal pressure, the section gradually changes from polygon to circle under the effect of internal pressure, and finally a circular annular shell is formed.

13

2023

/

03