Introduction to the use and production of large flanges

Published:

2023-03-13

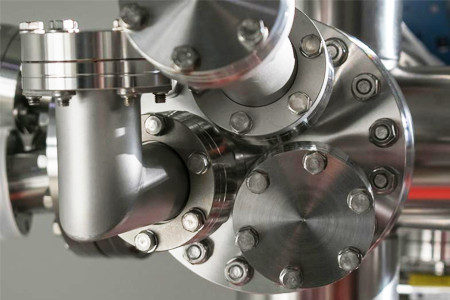

Common integral flanges include flat welding flanges and butt welding flanges. Large flanges have poor rigidity and are suitable for occasions with pressure p ≤ 4MPa; large flanges, also known as high neck flanges, have high rigidity and are suitable for occasions with high pressure and temperature.

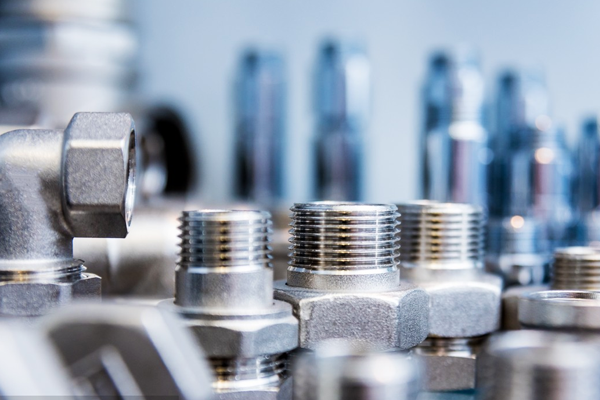

The commonly used is acid-resistant asbestos board. The gasket is a ring made of a material that can produce plastic deformation and has a certain strength. The large flange connection is a detachable connection. According to the connected parts, it can be divided into container flanges and pipe flanges.

According to the structure type, there are integral flanges, looper flanges and threaded flanges.

In high-pressure equipment and pipelines, metal gaskets of lens type or other shapes made of copper, aluminum, 10-gauge steel, and stainless steel are used.

The contact width between the high-pressure gasket and the sealing surface is very narrow (line contact), and the processing finish between the sealing surface and the gasket is high.

Common integral flanges include flat welding flanges and butt welding flanges.

Large flanges have poor rigidity and are suitable for occasions with pressure p ≤ 4MPa; large flanges, also known as high neck flanges, have high rigidity and are suitable for occasions with high pressure and temperature.

Related news